Ensuring Quality

Fundamental Philosophy

We will raise customer satisfaction and deliver new value for society by fully demonstrating the Sanki Engineering Group’s comprehensive capabilities and proposal-making capabilities to provide products that meet customer needs in each business area and for high-quality systems.

Quality Management System

The Company has acquired ISO9001, the international standards of a quality management system, on a company-wide basis. The Company will provide facilities, products and services that can be used by customers without concerns about quality, using its highly reliable technology under its quality assurance system.

| Business | Scope of Accreditation | Date of Acquisition | Inspection and Registration Organization Registration No. |

Accreditation board |

|---|---|---|---|---|

| Facilities Construction Business | Design, procurement and construction management of Heating, Ventilating, Air Conditioning, plumbing, electrical, advanced building automation & information communication technology and ancillary facilities for Buildings, Factories, Clean rooms, DHC systems and Nuclear plants, and project management for work environment establishment and relocation. | December 28, 1999 | ABS QE INC. 34863 |

ANAB RvA |

| Machinery Systems Business | Design, production, installation and maintenance service of Physical distribution systems and Material handling equipment. | March 30, 1998 | Japanese Standards Association JSAQ266 |

JAB |

| December 17, 2013 | Integrated into ABS QE INC. |

ANAB RvA |

||

| Environmental Systems Business | Design, engineering, manufacture, construction and after sales services of Environmental facilities. | March 27, 1998 | LRQA 958119 |

JAB |

| December 17, 2013 | Integrated into ABS QE INC. |

ANAB RvA |

- Note:

- ABS QE INC.: an inspection and registration organization in the USA; ANAB: an accreditation board in the USA; RvA: an accreditation board in Holland; LRQA: an inspection and registration organization in the UK; JAB: an accreditation board in Japan

Framework for Promoting the Quality and Environmental Management System

Customer Satisfaction Survey

In our work to improve construction quality, we conduct a customer satisfaction survey at the completion of construction work and reflect the feedback in our operations. In fiscal 2023, we received highly positive feedback from about 92%* of the 653 respondents. Looking ahead, we will continue to incorporate customer opinions into our operations to enhance construction quality.

- *

-

Calculated by regarding the following options in responses deemed as "highly positive feedback."

Facilities Construction Business: score of 4 ("Somewhat satisfied") or higher out of 5; Plants & Machinery Systems Business: score of 3 out of 3 ("High"); Environmental Systems Business: score of 70 points or higher out of 100

Sharing Information of Problems and Complaints

We accumulate and share our quality-related experiences across the Company by means of technical documents in order to prevent the occurrence of incidents and complaints related to quality or, in the event they do occur, to handle them quickly and effectively.

Information about problems and complaints are distributed to construction engineers through a flash bulletin, the "weekly bulletin" (a weekly meeting of the Problems and Claims Evaluation Committee, which is also attended by Group companies), and the "monthly bulletin," which discusses the causes of issues, corrective measures, and preventive measures.

Initiatives on Quality Based on Support for Construction Sites

To reduce the workload on construction managers and enable them to spend more time on construction work and quality management, and to maintain high quality, we provide operational support from the perspectives of site operations and design, technology and quality. We will also implement various measures under the Smile Site Plan to reduce the workload of construction managers, raise operational efficiency and enhance quality.

Site Support System

Initiatives for Improving Quality by Promoting DX

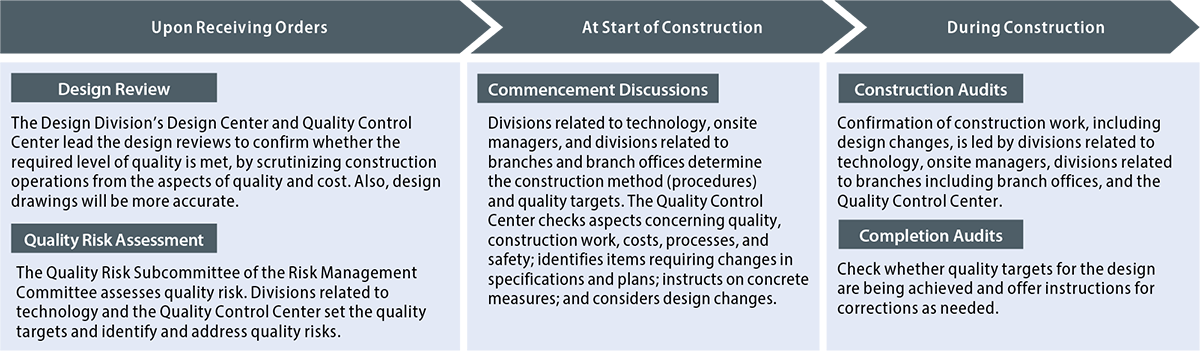

We are working on improving quality throughout the construction process from planning and design to completion. In design, we identify and resolve issues at an early stage to ensure quality by enhancing design reviews and improving the design accuracy.

In technological management, we facilitate onsite operations after the start of construction work by holding commencement discussions to decide on construction methods, procedures, and policies that result in higher quality and productivity. Moreover, we avoid falsifications and deficiencies in quality across all processes by having line staff and the Quality Control Center conduct stringent checks and followups. We will continue to improve quality and hand down technical expertise by having highly skilled quality assurance administrators and technical experts conduct audits during and after construction, implement quality confirmation and corrections, and mentor junior employees.

As a result of the revision of our quality manual and standards and reviewing of operational processes undertaken in fiscal 2021, the number of design reviews doubled in fiscal 2022. We also strengthened risk assessments at the upstream stage. These efforts have led to fewer problems, complaints, and corrections after construction and have helped prevent profitability from deteriorating.

Fostering Human Resources to Sustain Our Technological Level

The Sanki Techno Center fosters human resources by helping employees acquire basic skills, brush up on skills, and attain qualifications. New employees receive four and a half months of basic training and safety training.

The company conducts training for construction managers every three years, and the content is based on how many years of experience the manager has in their role. As for the skills of our engineers, we develop them through hands-on practice and drills using actual machinery and facilities at the Sanki Techno Center.

Number of Personnel with Quality-Related Qualifications (Totals as of April 1 for Each Fiscal Year)

| Qualification | FY2022 | FY2023 | ||

|---|---|---|---|---|

| Nonconsolidated | Consolidated | Nonconsolidated | Consolidated | |

| Professional engineer | 92 | 102 | 80 | 93 |

| Construction managing engineers (civil works/construction/electrical construction/pipe-laying works) | 1,125 | 1,277 | 1,061 | 1,225 |

| Architect | 37 | 42 | 38 | 42 |

| Facilities construction architect | 201 | 210 | 179 | 190 |

| Electrical engineers | 162 | 236 | 150 | 230 |

| Chief electrical engineers | 26 | 34 | 24 | 36 |

| First class instrument engineers | 297 | 306 | 284 | 294 |

| Fire protection engineers | 699 | 783 | 662 | 722 |

| Qualified managing engineers | 1,635 | 1,921 | 1,529 | 1,806 |

Major Skill Development Activities

| Initiatives | Training | Description of Training | Results |

|---|---|---|---|

| Initiatives at the Sanki Techno Center | Training for new employees |

|

64 participants |

| Correspondence course for attaining qualifications |

|

125 participants | |

| Training based on operational experience Third (fourth) year in construction work Sixth (seventh) year in construction work Ninth (tenth) year in construction work |

|

Held 8 times 114 participants |

|

| Initiatives for passing on technology | On-the-job training by technical experts |

|

25 technical experts made 1,343 site visits(cumulative total) |

| Initiatives for Group companies and subcontractors | Conference on electrical construction quality |

|

17 participating technicians from 18 subcontractors |

| Explanation of problems and complaints |

|

Number of sessions |